Calender Covers

Calender Covers

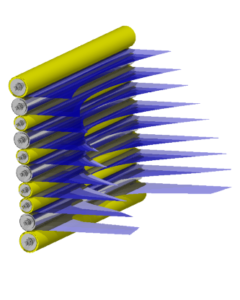

One of the last steps in making a paper sheet is to calender it using very hard rolls to obtain glossier surfaces and to even out nonuniformities. I had the honor or working with E.H. Jones on many projects in the field of supercalendering. We modeled the adverse effects of hot edges, general temperature variations, and incorrect crowning on the loading and bulk profiles. We also provided general advice for improving the sheet quality and for extending the life of the covered rolls. TAPPI chose our paper as one of the best in that decade. The figure on the left illustrates the high end loading that occurs when the hydraulics malfunction in the variable crown rolls.

Our modeling involved nonlinear finite element analyses that predicted the contact profiles between the rolls. Finite element analyses were also performed to estimate the thermal expansion distributions that resulted from temperature profiles. The roll covers were modeled as orthotropic composite materials. We also modeled paper physics to estimate the bulk progression through each nip. The results were visualized using a custom 3D graphics program. All the software was written in C++.

“On the Use and Care of Supercalender Rolls,” TAPPI Journal, Vol. 80, No. 2, Feb 1997, pp. 49-54, with E.H. Jones. Also presented at the 1996 TAPPI Finishing Conference, with E.H. Jones.

“Extending the Life of Synthetic Supercalender Covers,” Pulp & Paper Canada 98(2): T52-56, Feb. 1997, with E.H. Jones. Also presented at the 82nd Annual Meeting of the Technical Section, CPPA, at Montreal, QC, on Jan. 30 to Feb. 2, 1996, with E.H. Jones.