NipCalc

NipCalc

NipCalc is a nonlinear thermoviscoelastic finite element code that predicts roll cover stress and temperature distributions for paper making conditions. A paper sheet rides on a press felt and passes through the loaded zone, called a nip, that is formed between two rolls, as shown in the figure on the left. This pressing operation is designed to remove water from the paper sheet. One or both of the rolls may be coated with an elastomer, such as rubber or polyurethane, that is up to 3 inches thick, although the coatings are generally just under an inch thick. The soft coatings provide more gentile lower pressures for the fragile sheet and also are more forgiving if there are local sheet thickness variations. The coatings are replaceable, so they can be less expensive than refreshing the roll core metal. Since the elastomers have hysteresis, the cover temperatures can become excessive, so the program provides estimates for the temperature distributions. The program is used to design covers, confirm their safe application, and to estimate the shear stresses between layers to make sure there is no failure.

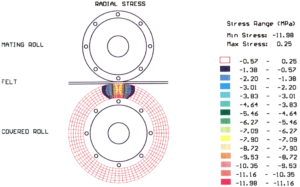

Engineers usually need to know the radial pressure acting on the paper sheet and within the roll cover. NipCalc’s postprocessor provides radial stress maps like the one shown on the left. Compressive pressure is negative for the mechanics community.

Engineers usually need to know the radial pressure acting on the paper sheet and within the roll cover. NipCalc’s postprocessor provides radial stress maps like the one shown on the left. Compressive pressure is negative for the mechanics community.

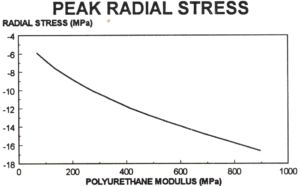

A major goal in engineering nips is to control the pressure applied to the sheet. As shown in the plot on the left, the compressive stress increases in magnitude as the cover material modulus increases. The engineers will frequently place softer roll covers in the early stages of the press section to keep the pressures low.

A major goal in engineering nips is to control the pressure applied to the sheet. As shown in the plot on the left, the compressive stress increases in magnitude as the cover material modulus increases. The engineers will frequently place softer roll covers in the early stages of the press section to keep the pressures low.

The performance and life of a roll cover may degrade rapidly at high temperatures. NipCalc can estimate the temperature distribution through the thickness of the roll cover to confirm that the cover is suitable for the application.

The performance and life of a roll cover may degrade rapidly at high temperatures. NipCalc can estimate the temperature distribution through the thickness of the roll cover to confirm that the cover is suitable for the application.

Crown shape and vibration studies often need to know the relationship between indentation and line load. NipCalc will output the penetration or the approach of the mating roll with respect to the covered roll. The inverse of the slope of the relationship shown in the plot on the left is the stiffness of the nip and can be used to estimate the natural frequencies of the system.

Crown shape and vibration studies often need to know the relationship between indentation and line load. NipCalc will output the penetration or the approach of the mating roll with respect to the covered roll. The inverse of the slope of the relationship shown in the plot on the left is the stiffness of the nip and can be used to estimate the natural frequencies of the system.

When I worked for Stowe Woodward, I considered NipCalc as the “flagship” program, since it served as the basis for many other studies.

Thermo-viscoelastic implies that the roll cover response is dependent on temperature and time. The materials behave as a combination of elastic solids and viscous fluids. The finite element program is nonlinear, since contact problems have nonlinear relationships between line load and nip width and line load and contact pressure. The material stiffness is also dependent on strain and temperature that are unknown initially. An iterative solution converges to the answers. The program was originally written as an extended DOS console application and was later migrated as a Windows executable. It is written in C/C++. The postprocessor outputs reports, 2D curves, and the colored contour plots shown above. It also exports to a variety of graphics formats so we can import the results into Adobe Illustrator and other presentation packages.

“A Tool for the Engineered Nip,” TAPPI Journal, Vol. 77, No. 3, March 1994, p. 117, with C.C. Moschel. Also presented at the 1993 TAPPI Engineering Conference, September, 1993, with C.C. Moschel.